Cow manure is typically used as fertilizer, but did you know this organic matter can also be turned into energy? Today, four basic processes are used: anerobic digestion, pyrolysis, torrefaction, and gasification. This article examines each process and provides links where you can find more information about using manure, a renewable resource, as a feedstock for energy generation.

Anerobic Digestion

Anaerobic digestion is a biological process where microorganisms break down manure in the absence of oxygen. First, the manure is fed into a sealed, airtight container known as a digester. Inside this container, naturally-occurring microorganisms break down (digest) the biomass. As decomposition occurs, a biogas that is rich in methane and carbon dioxide is produced. This biogas is collected at the top of the digester and can be used to generate heat or electricity. It can also be refined into a renewable natural gas.

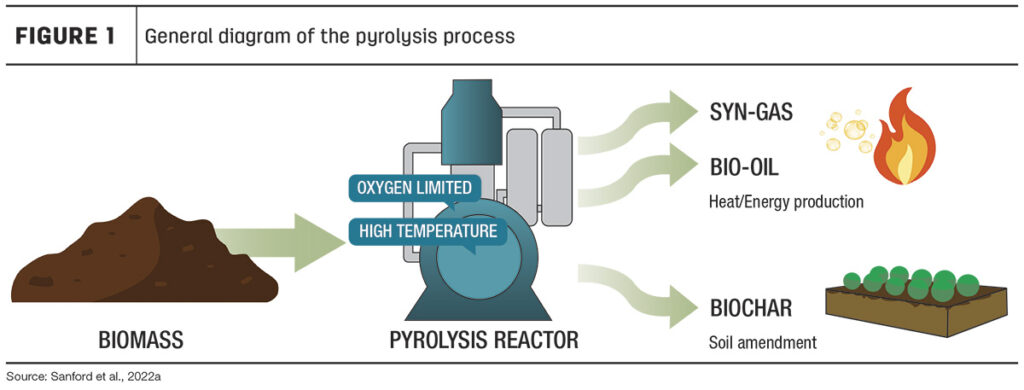

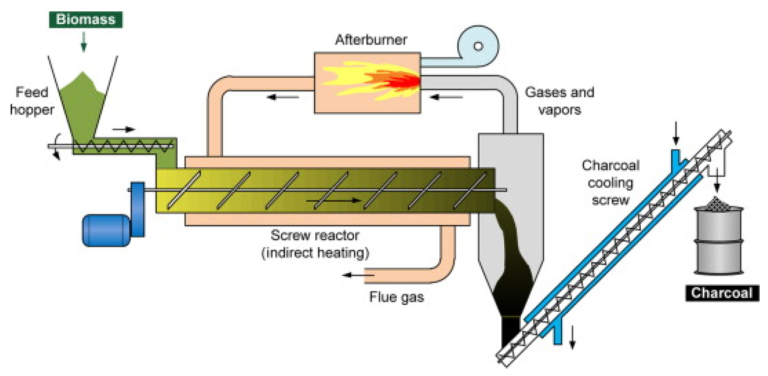

Pyrolysis

Pyrolysis also occurs in the absence of oxygen but is a thermal decomposition process instead of a biological one. First, animal manure is heated to a high temperature (400 to 800°C) in an oxygen-free environment. This organic material breaks down into three main products

- Biochar: A carbon-rich solid residue that can be burned as a solid fuel (like charcoal) or used in a fuel cell, a battery-like device that produces heat and electricity.

- Bio-oil: A liquid that can be used as a fuel in industrial boilers, furnaces, and power plants as a replacement for traditional fossil fuels like coal or oil.

- Syngas: A mixture of hydrogen and carbon monoxide that’s used to produce other fuels, typically methanol and diesel fuel.

Torrefaction

Torrefaction is a low-temperature version of pyrolysis that occurs at approximately 200 to 370°C. This process partly decomposes the manure and produces a solid charcoal-like product, biochar, with a high carbon content. Torrefied biomass can be converted into biofuels or densified into pellets for easier handling and storage. Known as green coal, torrefied biomass has a lower ash and mineral than coal and has a calorific content (8,500 – 10,500 BTU per pound) that is comparable to coal’s 11,000 BTU per pound.

Gasification

Gasification is a high-temperature (>700°C) thermochemical process that occurs in an oxygen-limited environment. The manure is fed into a high-temperature, high-pressure vessel where steam and a limited amount of oxygen causes a series of chemical reactions to occur. The end products are carbon monoxide, hydrogen, and carbon dioxide. This syngas can be combusted in engines to produce electrical energy or further converted into liquid fuels through Fischer-Tropsch synthesis, a catalytic process that produces a petroleum-like product called FT crude.